Service explanation for JA-114E

Wired code control panel with RFID and LCD Display

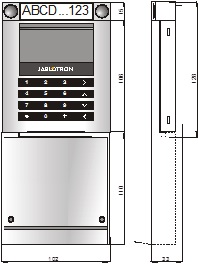

The control panel is part of the JABLOTRON JA-100 alarm system. Thanks to the simple system, it is possible to put together a configuration that is tailored to the installation size and the wishes of the users. The product must be installed by a trained technician with a valid Jablotron certificate.

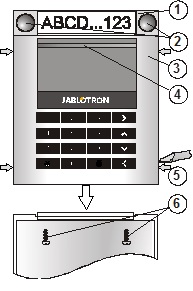

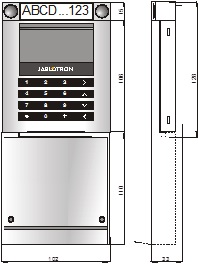

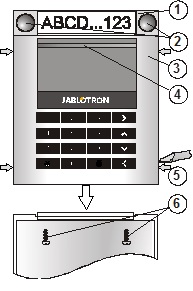

The control panel contains a display, RFID reader and the 1st control segment (1). This configuration can be expanded with the desired number of JA-192E segments (up to a maximum of 20 per configuration). The fold-out panel cover (6) can be removed if desired to provide permanent access. The panel also works as a reader of contactless access cards / tags (RFID).

Image: 1 – operating segment; 2 – segment keys; 3 – module control panel; 4 – illuminated activation key; 5 – clamps for opening; 6 – cover screws;

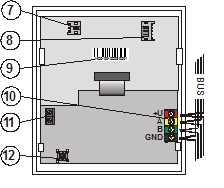

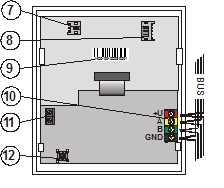

Image: 7 – audio module connector; 8 – connector operating segments; 9 – serial number; 10 – bus connection terminal; 11 – connection terminal for connecting audio module to the central unit, 12 – tamper switch;

Installation

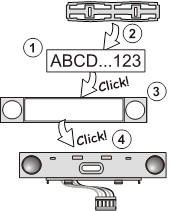

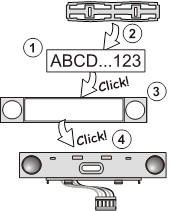

1. Press the four clamps on the sides one after the other (see Fig. 1) and detach the control panel from the plastic back wall.

2. When installing a next operating segment, first remove the closing cap at the top of the 1st segment.

3. Remove the transparent cover caps from segments (by pulling forcefully on both sides of the segment keys).

4. Always connect the guide wire of the segment to the connector of the previous segment and click them together (it is best to always rotate the guide wires by rotating the segment by 360° - this way the wires do not accidentally get wedged between the plastic parts). Install all desired operating segments in the same way. Finally, replace the closing cap (click it in).

5. Pull the cable through the plastic back wall and screw the back wall with segments at the selected location. When using multiple operating segments, also secure the segments to the wall (choose the number of screws as needed).

6. Connect the bus cable to the connection terminal (11).

Before connecting the BUS, the system must be disconnected from the power supply.

7. Connect the supply for segments to the internal connector of the control panel (8).

8. Click the control panel in the configuration.

9. Follow the instructions for installing the central unit. Basic steps:

a. After switching on, the yellow signal light flashes because the control panel is not part of the system.

b. In the F-Link program, select the desired position on the Peripherals card and start the learning mode with the Read button.

c. Press the illuminated activation button (4), which will cause the control panel to learn and the yellow light will go out.

10. After installation is complete, place the description labels in the cover caps of the segments and close the caps. Description labels are printed as part of the F-Link program (Peripherals card, at control panel position - Internal setting).

Image: Place description label in the operating segment.

Set properties

This is done by the F-Link program – card Peripherals. On control panel position Use Internal setting. The current configuration appears, with the option to set its properties. Individual segments can be assigned the desired functions (operating sections, signaling the status of sections, raising the alarm, operating the PG output, signaling the status of the PG output, etc.). Details can be found in the F-Link program.

Change configuration

If the configuration of segments needs to be changed, pull them apart at the point of connection, on the sides (on the side of the keys).

Technical parameters

Power supply from the control panel bus (9…15 V)

Power consumption in standby (idle) 15 mA

Power consumption for choice of cable 50 mA

Each added control segment 0.5mA

RFID frequency 125 kHz

Working temperature range -10 to +40 °C

Environment according to CSN EN 50131-1 II. inside, general

Classification grade 2

in accordance with CSN EN 50131-1, CSN EN 50131-3,

Furthermore complies with CSN ETSI EN 300330, CSN EN 50130-4,

CSN EN 55022, EN 60950-1

Conditions for operation CTÚ No. VO-R/10/09.2010-11

Product is designed and manufactured in accordance with the provisions applicable to it: Government Decree No. 426/2000 Coll. in the text of later promulgated regulations, provided that they are used according to their intended purpose.

Note: Although this product does not contain harmful materials, do not dispose of it in the household waste, but hand it in at the collection point intended for electronic waste.

The control panel contains a display, RFID reader and the 1st control segment (1). This configuration can be expanded with the desired number of JA-192E segments (up to a maximum of 20 per configuration). The fold-out panel cover (6) can be removed if desired to provide permanent access. The panel also works as a reader of contactless access cards / tags (RFID).

Image: 1 – operating segment; 2 – segment keys; 3 – module control panel; 4 – illuminated activation key; 5 – clamps for opening; 6 – cover screws;

Image: 7 – audio module connector; 8 – connector operating segments; 9 – serial number; 10 – bus connection terminal; 11 – connection terminal for connecting audio module to the central unit, 12 – tamper switch;

Installation

1. Press the four clamps on the sides one after the other (see Fig. 1) and detach the control panel from the plastic back wall.

2. When installing a next operating segment, first remove the closing cap at the top of the 1st segment.

3. Remove the transparent cover caps from segments (by pulling forcefully on both sides of the segment keys).

4. Always connect the guide wire of the segment to the connector of the previous segment and click them together (it is best to always rotate the guide wires by rotating the segment by 360° - this way the wires do not accidentally get wedged between the plastic parts). Install all desired operating segments in the same way. Finally, replace the closing cap (click it in).

5. Pull the cable through the plastic back wall and screw the back wall with segments at the selected location. When using multiple operating segments, also secure the segments to the wall (choose the number of screws as needed).

6. Connect the bus cable to the connection terminal (11).

Before connecting the BUS, the system must be disconnected from the power supply.

7. Connect the supply for segments to the internal connector of the control panel (8).

8. Click the control panel in the configuration.

9. Follow the instructions for installing the central unit. Basic steps:

a. After switching on, the yellow signal light flashes because the control panel is not part of the system.

b. In the F-Link program, select the desired position on the Peripherals card and start the learning mode with the Read button.

c. Press the illuminated activation button (4), which will cause the control panel to learn and the yellow light will go out.

10. After installation is complete, place the description labels in the cover caps of the segments and close the caps. Description labels are printed as part of the F-Link program (Peripherals card, at control panel position - Internal setting).

Image: Place description label in the operating segment.

Set properties

This is done by the F-Link program – card Peripherals. On control panel position Use Internal setting. The current configuration appears, with the option to set its properties. Individual segments can be assigned the desired functions (operating sections, signaling the status of sections, raising the alarm, operating the PG output, signaling the status of the PG output, etc.). Details can be found in the F-Link program.

Change configuration

If the configuration of segments needs to be changed, pull them apart at the point of connection, on the sides (on the side of the keys).

Technical parameters

Power supply from the control panel bus (9…15 V)

Power consumption in standby (idle) 15 mA

Power consumption for choice of cable 50 mA

Each added control segment 0.5mA

RFID frequency 125 kHz

Working temperature range -10 to +40 °C

Environment according to CSN EN 50131-1 II. inside, general

Classification grade 2

in accordance with CSN EN 50131-1, CSN EN 50131-3,

Furthermore complies with CSN ETSI EN 300330, CSN EN 50130-4,

CSN EN 55022, EN 60950-1

Conditions for operation CTÚ No. VO-R/10/09.2010-11

Product is designed and manufactured in accordance with the provisions applicable to it: Government Decree No. 426/2000 Coll. in the text of later promulgated regulations, provided that they are used according to their intended purpose.

Note: Although this product does not contain harmful materials, do not dispose of it in the household waste, but hand it in at the collection point intended for electronic waste.